Why Rajasthan Lime Suppliers Lead India’s Industrial Calcium Oxide Market

Why Rajasthan lime suppliers lead India’s industrial calcium oxide market – geological advantages manufacturing infrastructure strategic location competitive edge

Industrial procurement decisions in 2025 demand precise material selection to optimize operational efficiency and safety standards. For purchasing managers and technical buyers evaluating calcium-based solutions, understanding the fundamental differences between quick lime (CaO) and hydrated lime [Ca(OH)₂] proves critical for successful industrial applications. This comprehensive comparison addresses key selection criteria, performance characteristics, and cost implications for informed decision-making.

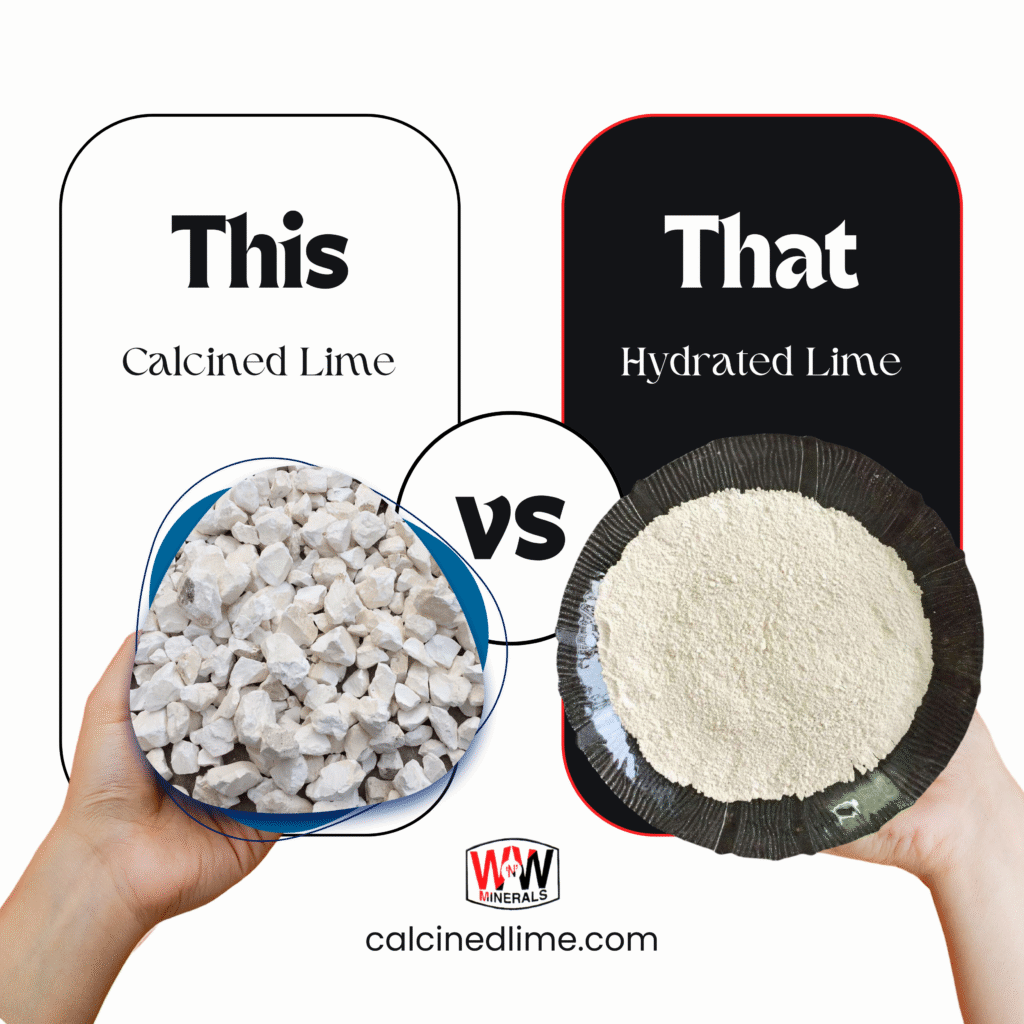

Quick lime, scientifically known as calcium oxide (CaO), represents the purest form of processed limestone. Created through calcination at temperatures exceeding 900°C, this highly reactive compound contains 90-95% calcium oxide content with minimal impurities. The production process removes carbon dioxide from limestone, leaving behind a highly caustic white solid with exceptional reactivity properties.

Quick lime demonstrates immediate exothermic reactions when exposed to water, generating significant heat during hydration. This characteristic reactivity makes it ideal for applications requiring rapid chemical responses and high-temperature processes.

Hydrated lime [Ca(OH)₂], also called slaked lime, results from the controlled reaction of quick lime with water. This pre-hydration process creates a fine powder with 200-400 mesh particle size, offering improved handling safety and storage stability. The molecular composition includes hydroxide groups that provide alkalinity while reducing the violent reactivity associated with quick lime.

Industrial buyers increasingly favor hydrated lime for its predictable performance characteristics and enhanced worker safety protocols.

Quick lime exhibits immediate and intense reactivity when exposed to moisture, generating temperatures up to 150°C during hydration. This exothermic reaction proves advantageous in metallurgical applications where rapid heating enhances process efficiency. However, this same characteristic creates handling challenges requiring specialized safety equipment and trained personnel.

Hydrated lime offers controlled reactivity without heat generation during application. The pre-hydration process eliminates surprise reactions, making it suitable for precise pH adjustment and chemical synthesis applications. This stability allows for easier transportation, storage, and handling in industrial environments.

In metallurgical applications, quick lime demonstrates superior performance for removing impurities from molten steel due to its high CaO content and aggressive reactivity. Steel manufacturers like SAIL and Tata Steel prefer quick lime for slag formation and temperature control in blast furnaces.

For water treatment operations, hydrated lime provides more predictable pH adjustment capabilities. Its hydroxide composition allows for gradual alkalinity increases without overshooting target pH levels, crucial for municipal water treatment and industrial effluent processing.

Quick lime excels in industrial wastewater neutralization where acidic conditions require immediate neutralization. Power plants utilize quick lime for flue gas desulfurization, achieving 95% SO₂ emission reduction.

Hydrated lime dominates municipal water treatment applications, providing controlled pH adjustment and heavy metal precipitation. Chemical plants prefer hydrated lime for acid spill remediation and routine pH maintenance.

Quick lime serves as a precursor for calcium carbide production, sodium carbonate manufacturing, and bleaching powder synthesis. Its high reactivity enables efficient chemical conversions in high-temperature processes.

Hydrated lime functions as a stabilizing agent in chemical synthesis, pharmaceutical production, and food processing applications. The pharmaceutical industry particularly values its consistent purity and predictable performance characteristics.

Quick lime requires controlled environment storage to prevent accidental hydration and maintain product integrity. Transportation costs increase due to hazardous material handling requirements and specialized equipment needs.

Hydrated lime allows for standard industrial storage conditions with conventional packaging options. Lower transportation costs result from reduced safety requirements and simplified handling procedures.

Quick lime typically costs 15-25% less per ton than hydrated lime due to reduced processing requirements. However, total cost analysis must include handling equipment, safety measures, and specialized storage infrastructure.

Hydrated lime commands premium pricing justified by enhanced safety, convenience, and consistent performance characteristics. Reduced handling costs and simplified logistics often offset higher unit prices for many industrial applications.

Quick lime advantages:

Hydrated lime advantages:

The 2025 industrial lime market shows growing preference for hydrated lime in water treatment and environmental applications. Stricter safety regulations and sustainability initiatives drive this transition, particularly in developed markets requiring enhanced worker protection standards.

Quick lime maintains dominant market position in steel production and heavy industrial applications where performance outweighs safety convenience factors. Major steel producers continue preferring quick lime for its superior metallurgical properties and cost efficiency.

Advanced lime processing technologies enable customized product specifications meeting specific industrial requirements. Smart packaging solutions improve handling safety while automated dosing systems optimize application precision for both lime types.

Choose Quick Lime when:

Select Hydrated Lime for:

The choice between quick lime and hydrated lime in 2025 depends on specific application requirements, safety priorities, and operational capabilities. Quick lime offers superior performance and cost efficiency for high-temperature industrial processes, while hydrated lime provides enhanced safety, convenience, and controlled reactivity for precision applications. Industrial buyers must evaluate total cost of ownership, including safety infrastructure, training requirements, and operational efficiency factors when making procurement decisions.

White ‘N’ White Minerals continues serving as a trusted partner for both quick lime and hydrated lime solutions, offering ISO-certified quality, reliable supply chains, and technical expertise to support informed material selection decisions across diverse industrial applications.

What are the main safety differences between quick lime and hydrated lime handling?

Quick lime presents higher safety risks due to its violent exothermic reaction with water, generating temperatures up to 150°C and potentially causing severe burns. Industrial facilities require specialized PPE, controlled storage environments, and comprehensive safety training. Hydrated lime offers safer handling characteristics as it’s already reacted with water, eliminating heat generation risks and requiring only standard industrial safety precautions.

Can quick lime and hydrated lime be used interchangeably in industrial applications?

No, quick lime and hydrated lime are not interchangeable due to their different molecular compositions and reaction characteristics. Quick lime (CaO) contains oxygen molecules while hydrated lime [Ca(OH)₂] contains hydroxide molecules that react differently in chemical processes. Applications requiring rapid reactions and high heat generation favor quick lime, while processes needing controlled pH adjustment and predictable performance benefit from hydrated lime.

How do storage and transportation costs compare between quick lime and hydrated lime?

Quick lime requires specialized storage facilities with strict moisture control and hazardous material transportation protocols, increasing logistical costs by 20-30%. However, its higher concentration allows for reduced shipping volumes. Hydrated lime permits standard industrial storage and conventional transportation methods, reducing handling costs but requiring larger shipping volumes due to lower concentration levels. Total logistics costs often favor hydrated lime for smaller volume applications.

Why Rajasthan lime suppliers lead India’s industrial calcium oxide market – geological advantages manufacturing infrastructure strategic location competitive edge

Industrial lime water treatment cost-effective solutions chemical plants environmental compliance pH control heavy metals neutralization White n White Minerals Jodhpur

Top 5 Steel Industry Applications of High-Purity Quick Lime from Jodhpur Manufacturers Jodhpur’s position as India’s lime manufacturing epicenter extends far beyond geographical advantage—it represents

Quick lime vs hydrated lime complete guide 2025 – industrial buyers comparison CaO Ca(OH)₂ applications safety handling White n White Minerals Jodhpur lime suppliers (159 characters)

India’s steel ministry has asked for 150 billion rupees ($1.74 billion) from the budget to offer mills incentives to produce low-carbon steel, two government sources

The Evolution of Lime Manufacturing in India: A Journey of Innovation and Growth The landscape of industrial manufacturing in India is a story of transformation,

All Rights Reserved White n White Minerals